Description

igluetech UK distributor of the Graco InvisiPac™.

This innovative tank-free melt-on-demand hotmelt delivery system is ready to use in under 10 minutes from cold.

It's engineered with a Tank-Free design, therefore the adhesive spends less time at high temperature, significantly reducing char and its negative effects, like blocked hoses and nozzles.

The Graco InvisiPac uses an integrated vacuum system to feed adhesive to an in-line melt chamber, the level is continuously monitored by a sensor and the system tops up automatically.

The melter has an efficient heat transfer design, the adhesive throughout is equivalent to or better than many tank based hotmelt systems. And with no tank lid or volume of high temperature melted glue accessible to personnel the health and safety benefits speak for themselves

You finally have a hotmelt system that runs reliably, unnoticed and invisible.

Why the invisiPac is different and better!

Tank-based systems have long heat-up times, which cause operators to leave systems on, and do expose the adhesiveto extended periods of heat.

This degrades material qualityand produces time-consuming, plug-forming char. Tank-basedsystems are also prone to thermal shock from large amounts of

adhesive being dumped into the tank during refill.

This causes temperature fluctuation and changes glue viscosity, thus wasting glue through dispensing inconsistencies.

With invisiPac:

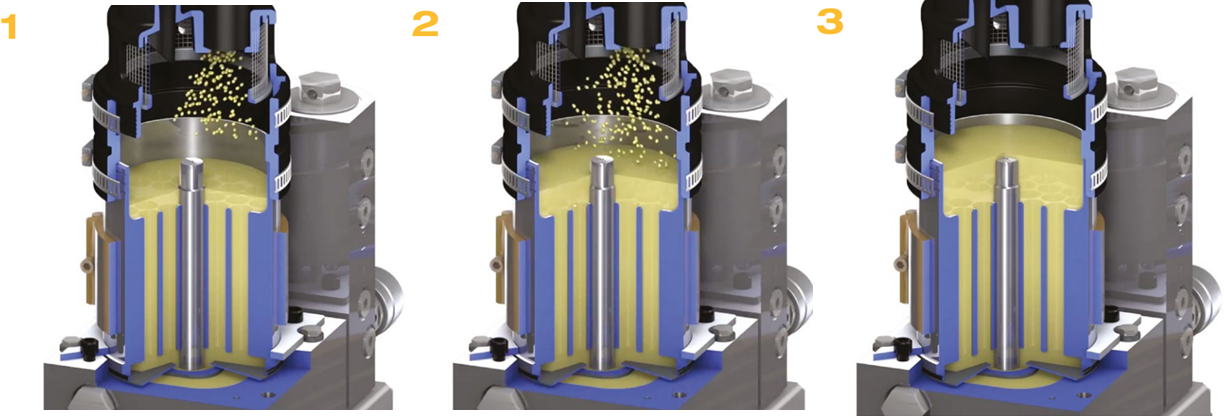

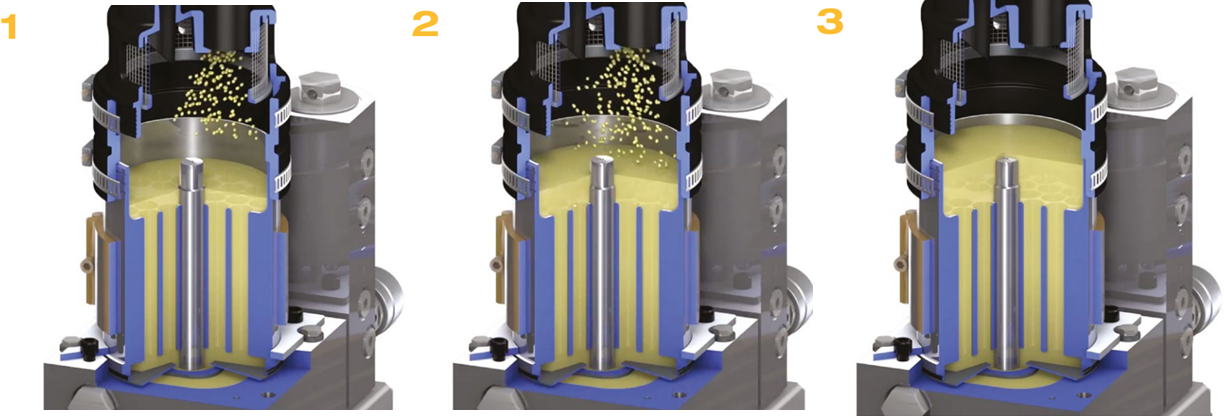

- An ultrasonic sensor monitors the glue level in the melting

chamber, automatically adding glue when needed.

- With its efficient heat transfer design, glue melts quickly

and maintains a consistent temperature.

- The less time your glue sits at high temperature means less char and maintenance.

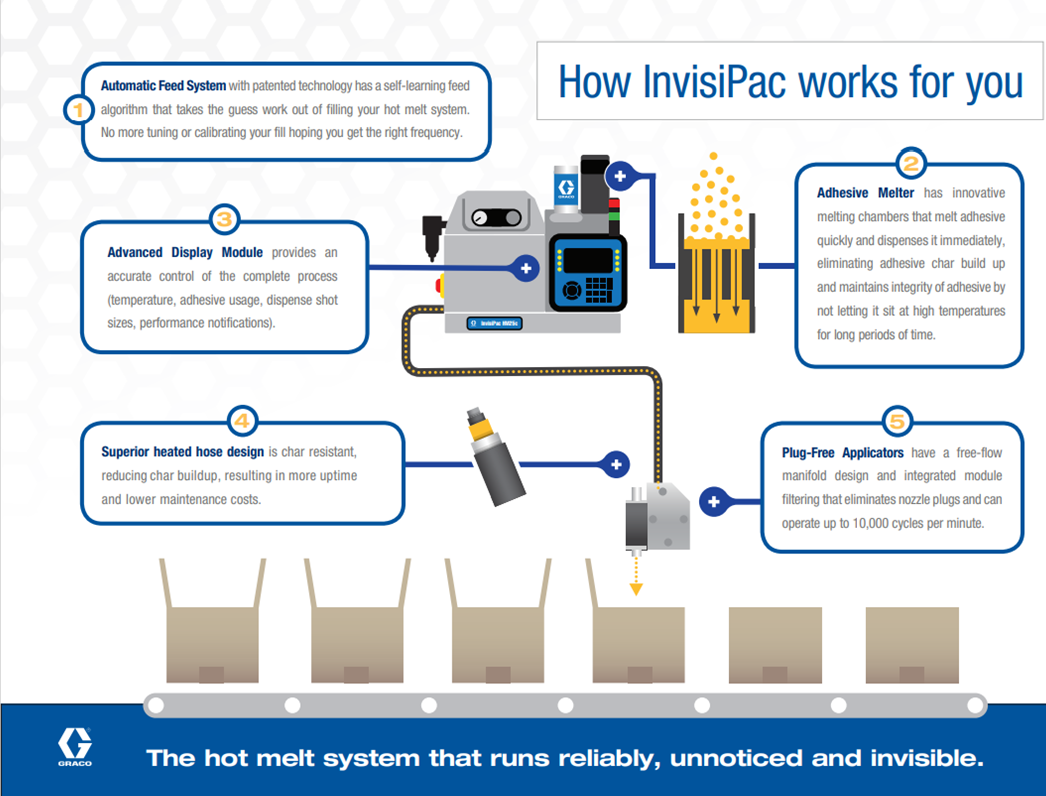

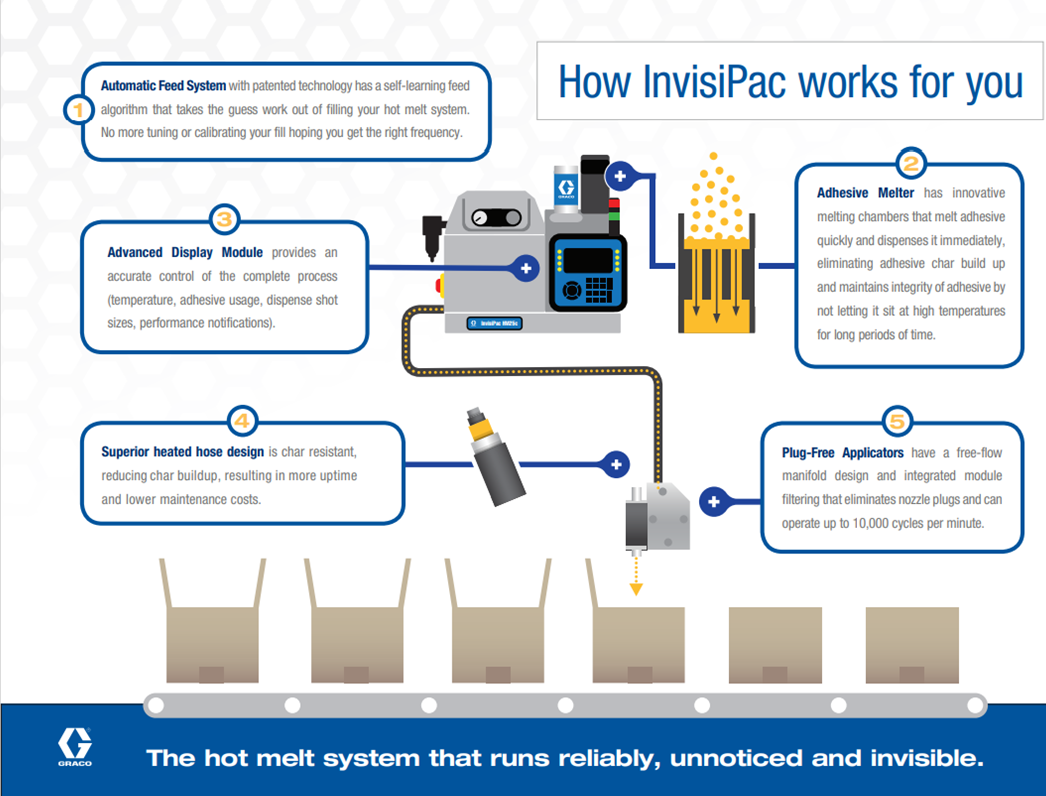

How invisipac Works For You

- Automatic Feed System with patented technology has a self-learning feed algorithm that takes the guess work out of filling your hot melt system.

No more tuning or calibrating your fill hoping you get the right frequency

- Adhesive Melter has innovative melting chambers that melt adhesive quickly and dispenses it immediately, eliminating adhesive char build up and maintains integrity of adhesive by not letting it sit at high temperatures for long periods of time.

- Advanced Display Module provides an accurate control of the complete process (temperature, adhesive usage, dispense shot sizes, performance notifications).

- Superior heated hose design is char resistant, reducing char buildup, resulting in more uptime and lower maintenance costs.

- Plug-Free Applicators have a free-flow manifold design and integrated module filtering that eliminates nozzle plugs and can operate up to 10,000 cycles per minute.