We get asked by print finishers, packaging machinery plants and all businesses that use hotmelt glue systems and cold glue application machinery this very question. To control a glue application system, the best solution is to buy a glue pattern controller.

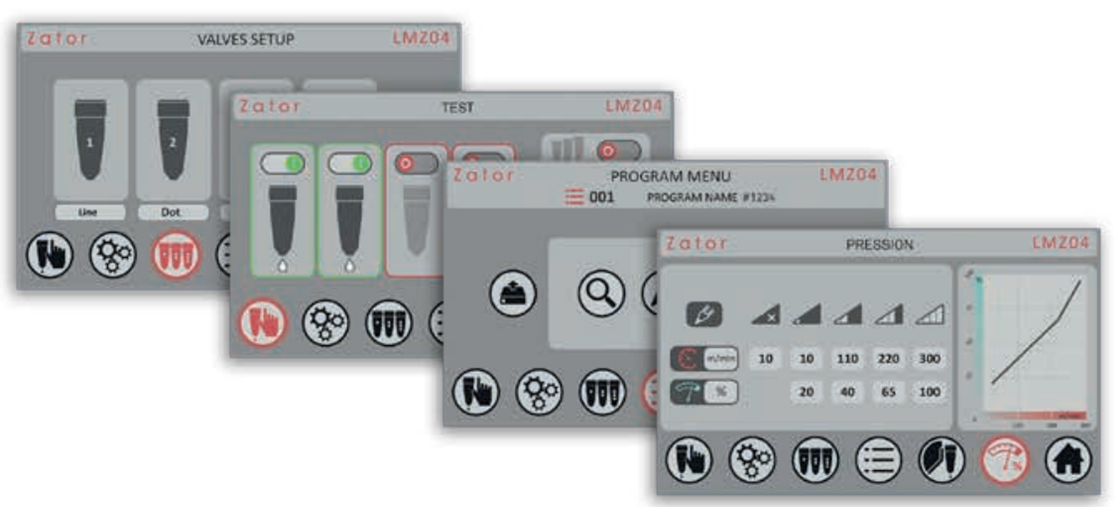

The design of the graphic interface of the glue pattern controller lets the user change the speed and simplify the learning of the basic functions of the instrument.

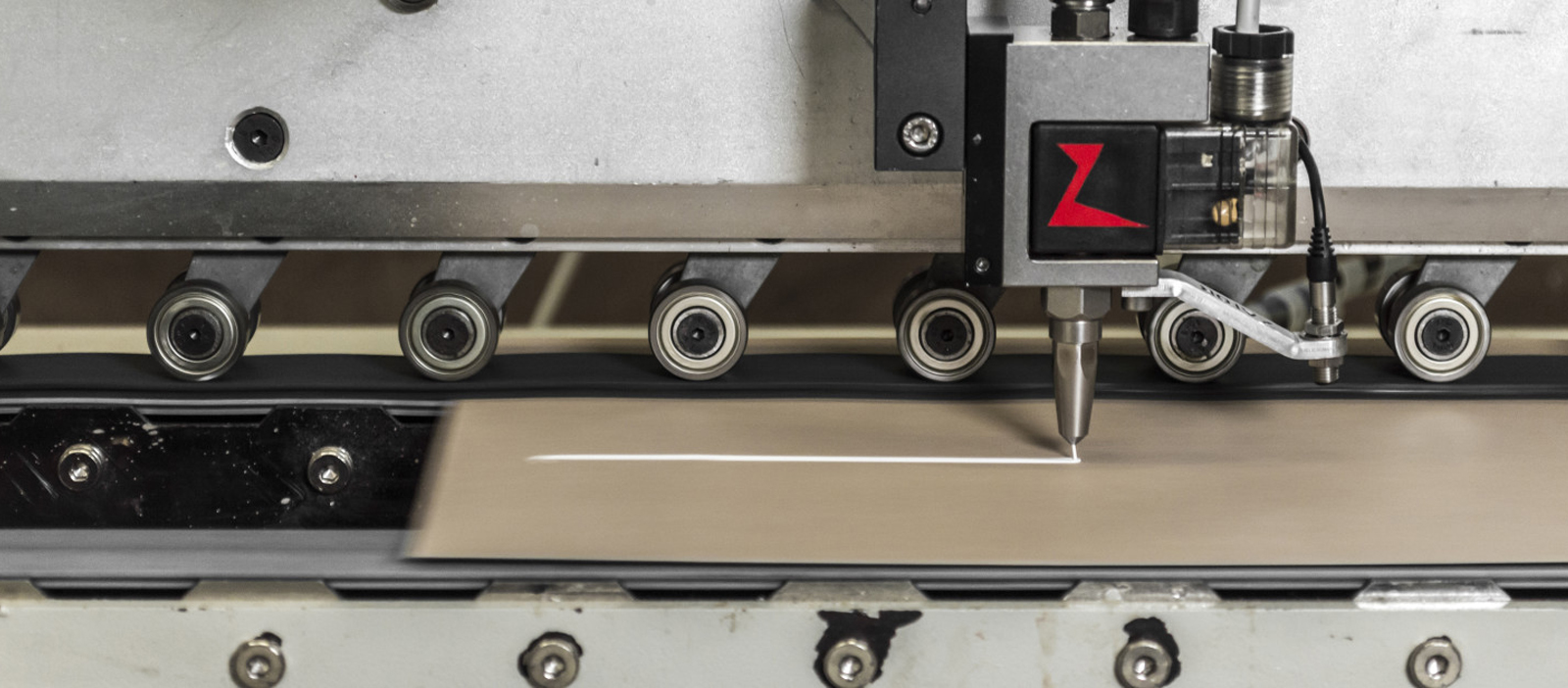

The design and versatility means it can control glue application head valves in applying either dot or line patterns onto your product very accurately.

With the LMZ pattern controller you can switch the glue application head on and off with a touch of a button.

The LMZ Pattern Controller microprocessor controls have been designed and manufactured to be used on different types of high speed machinery where glue application is required.

The design and versatility of the LMZ Pattern Controller means it can control glue application head valves in applying either dot or line patterns onto your product very accurately.

The microprocessor controls can store up to 99 different programs and can handle up to 96 independent valves (or channels). Each of them are able to perform four or eight different glue lines.

The valves can work in lines or dots mode, a programmable function allow to switch automatically from dot to line at programmed speed.

The design of the control can be used with two different modes:

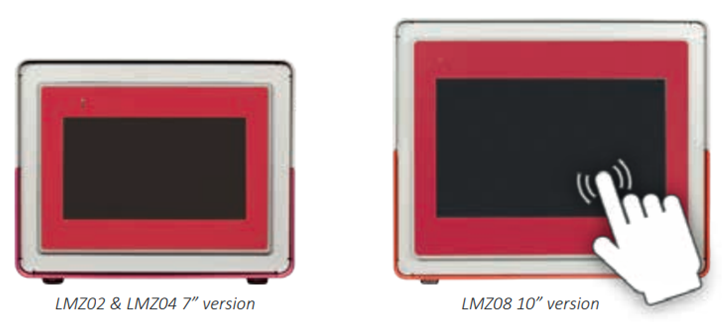

More Simple. More Intuitive.

The design of the graphic interface lets the user adjust the speed and simplify the learning of the basic functions of the

instrument.

You won’t need any other devices to operate on the instrument.

Just use your fingers.

You can keep an eye on all the glue patterns data, simplifying the reading

and preventing possible mistakes during the programming.

Connect with wi-fi your mobile devices like smartphone or tablet to the control to remotely

control in real time the production and make any corrections to the program.

*Available for Android and iOS devices.